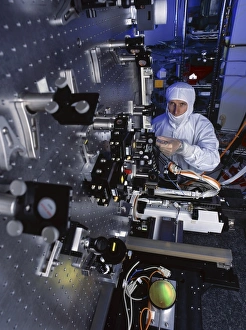

Clean Room Collection

"Inside the Neil Armstrong Operations and Checkout Building: Witnessing History in Silicon Valley's Clean Room" Step back in time to August 1978

All Professionally Made to Order for Quick Shipping

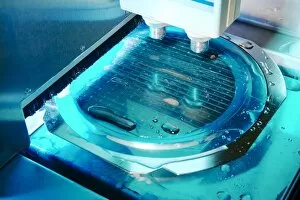

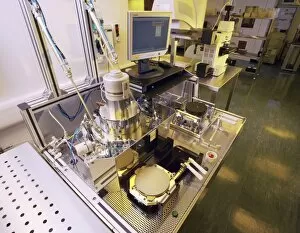

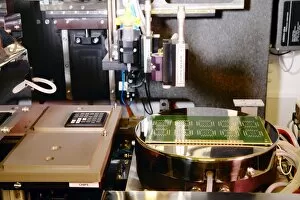

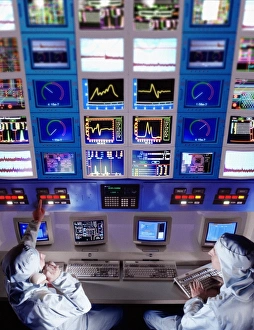

"Inside the Neil Armstrong Operations and Checkout Building: Witnessing History in Silicon Valley's Clean Room" Step back in time to August 1978, where workers inside the Neil Armstrong Operations and Checkout Building high bay at NASA's Santa Clara facility were making groundbreaking strides. In this iconic clean room located in the heart of California's renowned Silicon Valley, history was being made as space exploration reached new heights. As you enter this hallowed ground, your eyes are immediately drawn to a photograph taped to one of the walls. It showcases all four Magnetospheric Multiscale (MMS) spacecraft stacked together, a testament to human ingenuity and technological advancements. Moving further into the clean room, you catch sight of a work station bustling with activity. Here, technicians meticulously secure the Orion crew module for NASA's Exploration Mission 1 (EM-1), ensuring its readiness for an extraordinary journey beyond our atmosphere. The dedication and precision exhibited by these workers is awe-inspiring. They carefully maneuvered the Orion crew module pressure vessel, an essential component of EM-1, showcasing their commitment to pushing boundaries and exploring uncharted territories. In every corner of this expansive clean room lies evidence of innovation. Thermal protection system panels stand tall in view within the high bay area - guardians against extreme temperatures encountered during space missions. Your gaze then falls upon an array of space hardware specifically designed for the Orion crew module. These intricate pieces represent countless hours spent perfecting each detail - a testament to humanity's unwavering determination to conquer frontiers unknown. Finally, your attention is captivated by none other than the Orion heat shield undergoing meticulous processing within these very walls. This critical element ensures astronauts' safety as they brave re-entry into Earth's atmosphere after venturing far beyond our planet's confines. Stepping out from this historic clean room evokes a sense of wonderment about what lies ahead for humanity in its quest for discovery among distant stars.